Thailand’s food and beverage industry depends heavily on cold-chain logistics to transport temperature-sensitive goods like seafood, dairy, and beverages. To maintain product quality and meet export standards, Trakzee’s temperature monitoring system offers real-time visibility to prevent spoilage, ensure compliance, and build customer trust.

Cold-Chain Fleet Monitoring for Food & Beverage Distribution in Thailand

Introduction

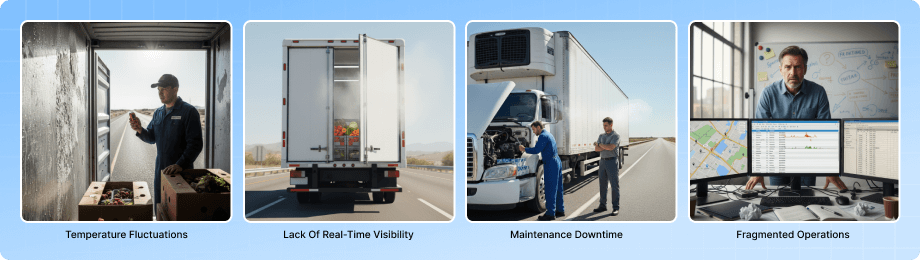

Challenges

- Temperature Fluctuations: Manual temperature checks can’t ensure constant monitoring, leading to product spoilage during long routes.

- Lack of Real-Time Visibility: Fleet operators struggle to track temperature or door status across multiple vehicles simultaneously.

- Driver Behaviour Issues: Harsh driving, excessive idling, or unauthorized stops impact both fuel efficiency and product safety.

- Maintenance Downtime: Refrigerated units often face breakdowns due to delayed maintenance.

- Fragmented Operations: Many SMB fleet owners lack integrated tracking systems connecting vehicles, temperature sensors, and logistics teams.

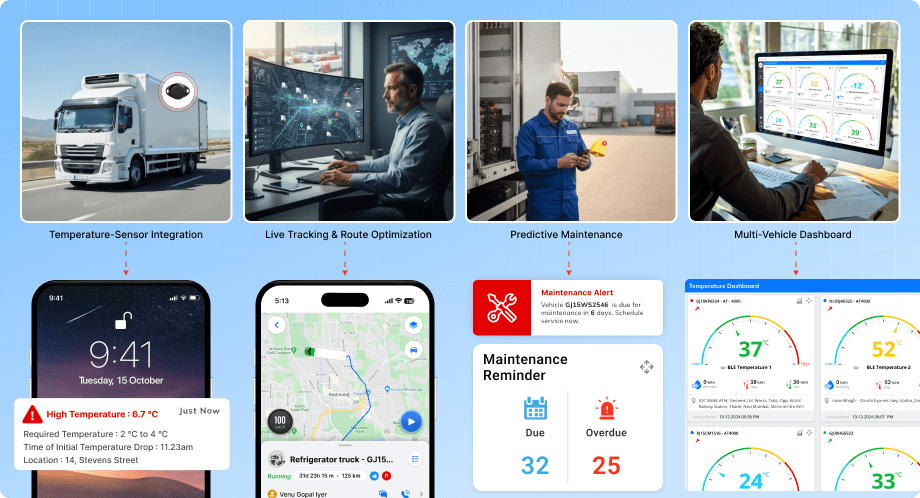

Solution with Trakzee

The fleet management software combines GPS tracking, IoT sensors, and predictive analytics to give operators full control of their cold-chain vehicles:

- Temperature-Sensor Integration: Continuously monitors and logs cargo temperature, sending alerts for deviations.

- Live Tracking & Route Optimization: Displays vehicle position and suggests efficient routes to reduce travel time and idling.

- Driver Behaviour Monitoring: Detects harsh driving, overspeeding, or sudden braking, helping ensure safer deliveries.

- Predictive Maintenance: Uses real-time data to anticipate refrigeration or vehicle maintenance needs.

- Multi-Vehicle Dashboard: Offers unified insights into all temperature-controlled fleets on a single screen.

Results Achieved

- Reduced Spoilage: Up to 20–30% drop in product loss due to early temperature alerts and continuous monitoring.

- Improved Fleet Utilization: Route optimization and driver analytics led to a 15% increase in delivery efficiency.

- Faster Maintenance Response: Predictive maintenance cut unplanned downtime by 25%.

- Compliance Ready: Temperature logs helped fleets meet export quality and food-safety standards effortlessly.

- Enhanced Customer Trust: Real-time delivery visibility improved client satisfaction and repeat business.

Let’s Move Forward, Together

Share your details and we’ll guide you from here.