Why Warehouses Are Adopting Indoor Mapping Software for Better Space Visibility

Warehouses today are under constant pressure. Order volumes are rising. Delivery timelines are shrinking. At the same time, floor space remains limited and costly. This is why indoor mapping software is becoming a critical tool for modern warehouse operations. Instead of relying on static layouts and manual coordination, warehouses now want real-time space visibility that reflects what is actually happening on the floor.

What space visibility means in warehouse operations

Space visibility in warehouses is not just about layout drawings. It is about operational awareness.

It means:

- Knowing where inventory, zones, and racks exist

- Seeing how space is occupied during daily operations

When space visibility is strong, warehouse teams can quickly answer questions like:

- Which areas slow down picking?

- Where is congestion building during peak hours?

- Which zones are not being used effectively?

This level of clarity is difficult to achieve with traditional methods.

Why traditional warehouse methods no longer work

Many warehouses still depend on outdated methods to manage space. These methods fail as operations scale.

Common limitations of traditional approaches:

- Static floor layouts

These do not update when racks move or temporary zones are created.

- Manual coordination

Verbal instructions and paper-based plans break under volume pressure.

- GPS dependency

GPS does not work reliably indoors. Location accuracy suffers.

- Blind spots in temporary storage

Overflow zones often remain invisible to managers.

As warehouses grow, these gaps directly impact productivity and order accuracy.

The growing need for indoor mapping in warehouses

Warehouse operations are changing rapidly. Several industry forces are driving adoption.

Key reasons behind the shift:

- E-commerce growth

Higher order frequency demands faster picking and put-away.

- Labor efficiency challenges

Workers cannot waste time navigating unclear layouts.

- Same-day and next-day delivery expectations

Delays inside warehouses affect the entire supply chain.

- Smart warehouse initiatives

Data-driven decisions require real-time spatial intelligence.

Indoor mapping aligns perfectly with these operational realities.

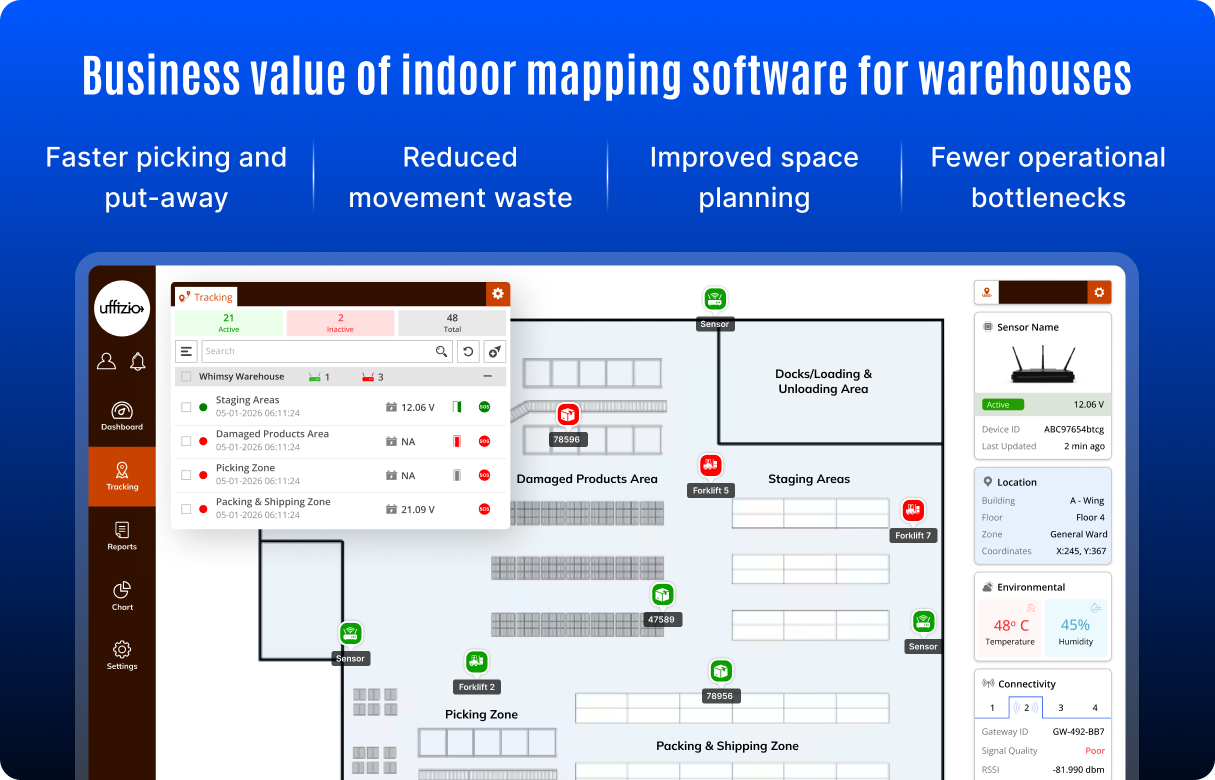

How indoor mapping software works in a warehouse environment

Indoor mapping software creates a digital representation of the warehouse floor. This representation reflects zones, pathways, and space usage dynamically.

At an operational level, it enables:

- Digital visualization of warehouse layouts

- Zone-level space awareness

- Clear identification of movement patterns

- Reduced dependency on verbal or manual instructions

An indoor mapping platform does not replace warehouse processes. It strengthens them by adding visibility and structure.

Indoor mapping and workforce productivity

Warehouse productivity depends heavily on movement efficiency.

Indoor mapping helps by:

- Reducing time spent searching for locations

- Minimizing cross-traffic between zones

- Supporting faster onboarding of new workers

- Enabling standardized workflows

When workers understand space clearly, performance becomes consistent.

Why warehouses prefer indoor mapping over manual tools

From a B2B perspective, scalability and repeatability matter.

Manual tools fail because:

- They depend on individual experience

- They do not scale across multiple sites

- They lack real-time adaptability

Indoor mapping software provides:

- Standardized space visibility across warehouses

- Easier replication across locations

- Data-backed insights for leadership decisions

This makes it a long-term operational investment.

Common use cases across warehouse

Indoor mapping is relevant across multiple warehouse environments.

Typical applications include:

- E-commerce fulfillment centers

- Third-party logistics warehouses

- Manufacturing storage facilities

- Cold storage operations

Each environment benefits from improved space visibility.

Key considerations before adopting indoor mapping software

Important factors to assess:

- Accuracy of indoor location representation

- Ease of layout updates

- Scalability across sites

- Compatibility with existing workflows

The goal is operational clarity, not complexity.

The strategic advantage of space intelligence

Warehouses generate massive operational data. Without spatial context, this data remains incomplete.

Indoor mapping converts space into a measurable asset. It enables:

- Smarter layout decisions

- Better workforce planning

- Improved long-term capacity utilization

This intelligence supports sustainable growth.

Summary

Warehouses can no longer afford blind spots. Space visibility directly affects efficiency, cost, and service quality. Indoor mapping software addresses this challenge by turning warehouse layouts into live, actionable insights. For B2B organisations, adopting an indoor mapping platform means moving from reactive operations to controlled, data-driven execution. It is a practical step toward smarter warehouse management.